One of the last side projects I worked on before leaving Big Nerd Ranch was to build a kegerator for the office. We wanted to have beer and nitro iced coffee on draft. We didn’t want to buy a setup for carbon dioxide and nitrogen so we built one.

One of the last side projects I worked on before leaving Big Nerd Ranch was to build a kegerator for the office. We wanted to have beer and nitro iced coffee on draft. We didn’t want to buy a setup for carbon dioxide and nitrogen so we built one.

I’d posted before about working as an electro-mechanical engineer. Eventually, I left that position to attend grad school. I never wrote about finishing up my work, and left much unmentioned in my prior post. I hope wrap up my involvement at ____ by talking about and showing off some of the projects I was responsible for.

I never got around to posting about my time at Georgia Tech’s Center for Assistive Technology and Environmental Access (CATEA), where I was a researcher and shop manager. CATEA designs and tests all sorts of technology to help disabled people. The entire lab is a sort of skunk works operation; imagine Myth Busters “what crazy thing do you want to try today”. I was responsible for bringing to life the ideas and inventions of several Georgia Tech professors and their grad students. I had an entire shop at my disposal and best of all a Georgia Tech VISA card!

Continue reading “Past Work: Center for Assistive Technology and Environmental Access”

Its official! I’ve graduated. Man, what an experience. This has been one of the most rewarding decisions of my life. Its hard to imagine what will happen next. I have day-dreamed and focused on grad school for so long that I didn’t spend much effort looking past this moment. Continue reading “Grad School, Peace Out!”

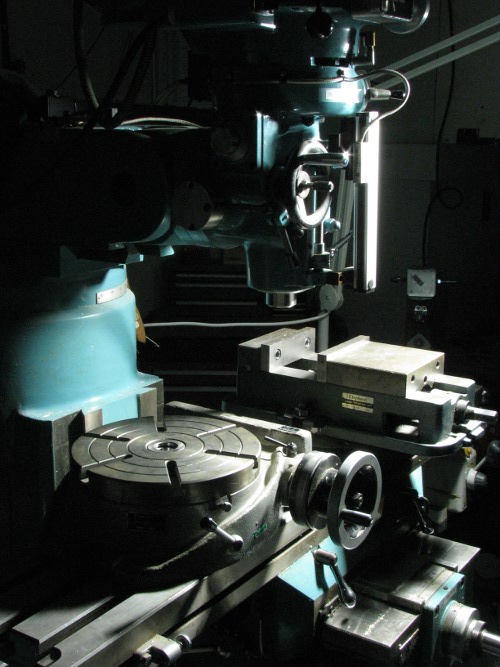

To use the CMU machine shop full time, I had to take a small course on machining. The class was straight forward, and I knew about 75% of what was taught. I did learn a lot though and picked up some new tricks. We learned the main concepts through two small projects, a pencil holder and a plumb-bob, performing the cutting operations ourselves. Once the skill was demonstrated, we moved on, so most people didn’t finish the projects. However, I spent a little time after class putting the finishing touches on the parts. I’ve machined a million parts for previous jobs but never had the opportunity to display them. While these two parts are pretty basic and not a good indicator of my skill level, I thought it would be fun to “do it right”.