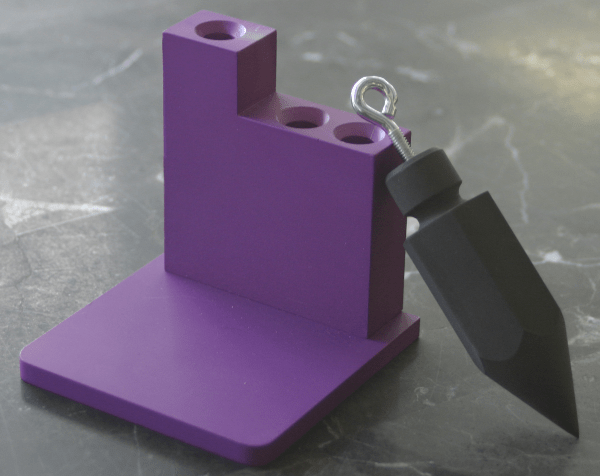

On my single speed bike, I run front and rear brakes. However the frame doesn’t have cable routing bosses on the top tube. Right now I just have the cable housing zip-tied to the frame. This isn’t a very elegant solution and I wanted to improve it.

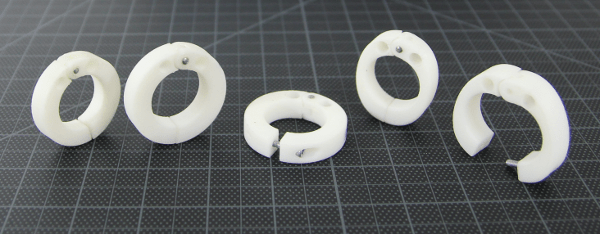

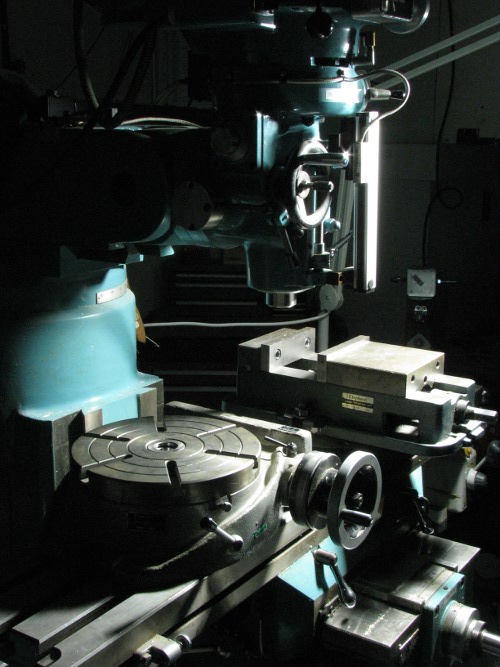

Problem Solvers makes a nice clamp that will route two cables. Unfortunately they don’t make them to fit my 1.0 inch top tube. Carnegie Mellon has a 3D printer and I had always wanted to experiment with rapid prototyping parts. It is very easy to design a part in Solidworks and then export it to the 3D printer. I thought I could design and fabricate something to fit my need.